Food Safety

Reduce results from days to hours

Assuring Food Safety and Quality

The ever-increasing worldwide demand for high quality food products, emphasizes the importance of proper microbiological monitoring.

Assuring food safety and quality is our vision. Through our innovative technology, IntuBio strive to assure the availability of biologically safe food by implementing fast microbiological monitoring on or close to the production floor, where the decisions are made.

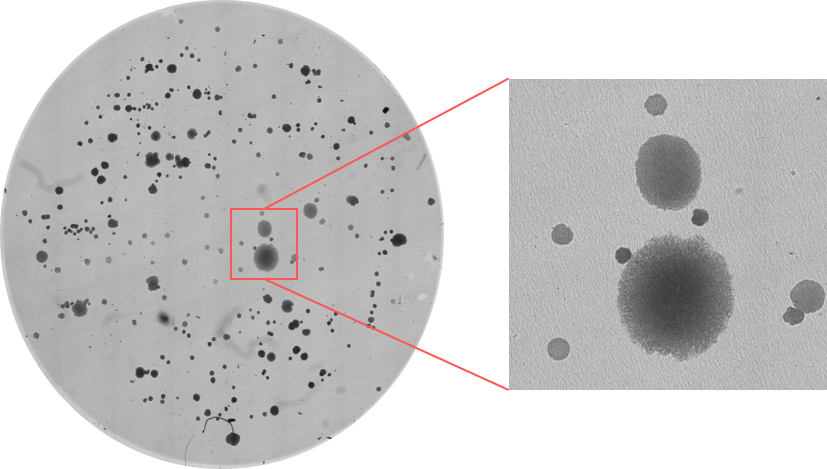

- CFU in hours, not days

- Easy sample prep

- Automated colony counting

- Continuous growth monitoring

- Easily interpreted data presentation

- Results as CFU, not arbitrary units

Every type of food has its own challenges

Meats

Meat is highly susceptible, if not processed properly, to spoilage by a variety of microorganisms. The nature of the meat processing can easily introduce bacteria from fecal matter such as E. coli or Salmonella.

On packaging lines Listeria may roam, and can be introduced to ready-to-eat products where they proliferate, even under refrigeration.

Thus, proper microbiological monitoring programs are important.

Beverages

The beverage industry is characterized by acidic products driving the microbiological population towards acid tolerant organisms.

These most commonly include fungi, yeast and aciduric bacteria. Spoilage rarely pose a threat to consumer health, but mainly cause decreased shelf life and off-taste. Proper microbiological control programs must be in place to ensure reduced scrap cost and optimal process flow.

Vegetables

In developed countries, fresh vegetables contaminated with fecal bacteria, have frequently cause remarkable outbreaks. As many vegetables are consumed without heat treatment, pathogenic bacteria, introduced from polluted water can be ingested and cause disease.

The most common bacteria responsible for these outbreaks are E. coli and Salmonella, however, Listeria and other pathogens can be introduced through handling and storage.

Dairy

Dairy products are highly susceptible to contamination with pathogenic and spoilage organisms. Pathogens are commonly found in untreated milk, such as E. coli, Salmonella, staphylococci, Listeria and Bacillus cereus. The spore-forming Bacillus cereus are infamous for infecting whole factories with difficult and expensive cleaning required.

Proper monitoring programs are highly important to ensure consumer safety, improve shelf life and optimize production costs and flow.

Ingredients

The large scale processing of food ingredients requires zealous control and thorough microbiological monitoring programs, to ensure both consumer safety and stable high quality products.

The ingredients industry consequently requires understanding of the microbiological load at every step along the processing line, for optimized yield, manufacturing cost, consumer safety and appropriate shelf life.

Seafood

As one of the most traded commodities worldwide, it is imperative that food safety is up to standard.

The major microbiological issue in the seafood industry remains to be contamination by Listeria.

This contamination can occur at any point during processing, emphasizing the importance of widespread and consistent microbiological sampling.

Foodborne Diseases

The modern food industry goes far beyond the small scale production of the past, and now thousands of consumers get their products from the same lines.

For that reason safety is paramount. With more than 420.000 deaths worldwide every year, and 1 in 10 people falling ill from foodborne illnesses, this problem is certainly not a thing of the past.

A major contributor to this death toll is the diarrhoeal diseases caused by bacteria while others cause illnesses with severe impact on the health, such as Listeria monocytogenes.

Monitoring Programs

In the 1950s the American space program establish a food safety monitoring program known as HACCP (Hazard Analysis and Critical Control Points). This approach was eventually adapted by most food producers worldwide, to ensure safe products and full control of the whole food chain.

The flexibility of our solutions helps to increase sampling frequencies with significantly reduced time-to-result to improve product quality, consumer safety and process flow in the food industry. With IntuGrow it is possible to determine TVC and test the common pathogens in one analysis with results in few hours. This enables a thorough overview of the state of the process line with full transparency of the microbial load at multiple CCPs.

Learn more about how IntuGrow can help ensuring food safety.

Reduce results from days to hours

- Result as CFU

- In a fraction of time

- Meet volume requirements

- Non-destructive